Epitaxial Reactors

Single wafer epitaxial reactors

with high growth rate produces high quality epi film.

Features

Core Technology

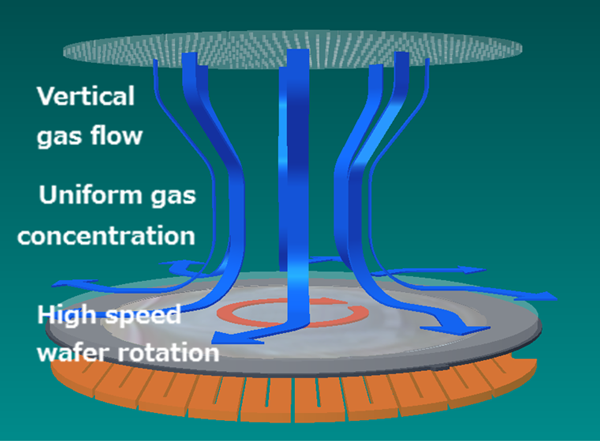

Principled deposition technology

A combination of vertical gas flow and high-speed wafer rotation forms a uniform, ultra-thin boundary layer(*) above the wafer.

A thin boundary layer easily takes source gas in and exhausts HCl gas with centrifugal force.

As a result, the following reaction is observed, leading to 20 to 30% of high gas conversion rate which brings high-speed growth.

- 1. SiHCl3 → SiCl2* ↓ + HCl ↑SiCl2* generated through thermal decomposition is absorbed onto the wafer surface.

- 2. SiCl2* + H2 → Si ↓ + 2HCl ↑ Single crystal silicon grows on the wafer surface.

- (*) Boundary layer is an area in the thickness direction where the deposition reaction occurs above the wafer surface.

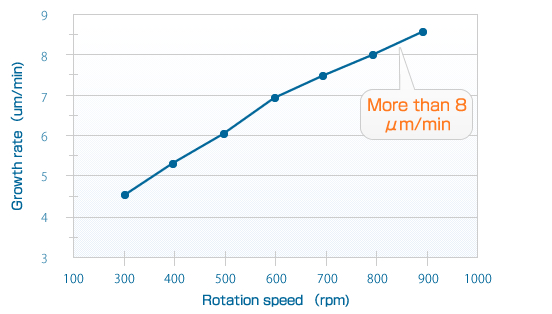

Advantages of High-speed Wafer Rotation

Faster rotation brings higher growth rate.

Gas conversion rate changes according to wafer rotation speed. As a result, epi growth rate becomes higher with faster rotation.

Source our company (HT2000FD)

System Specifications(HT2000FD)

| Wafer size | 200mmφ |

|---|---|

| Heating method | Resistance heating from backside |

| Process temperature | 800 - 1,150℃ |

| Rotation speed | 300 - 900rpm |

| Pressure | 93(700) - 13.3(100)kPa(Torr) |

| Gases | SiHCl3, SiH2Cl2, H2, HCl |

| Outer dimension (Main frame) | 1,396mm(W) × 2,276mm(D) × 2,350mm(H) |

| About 2,300 kg | 約2,300Kg |

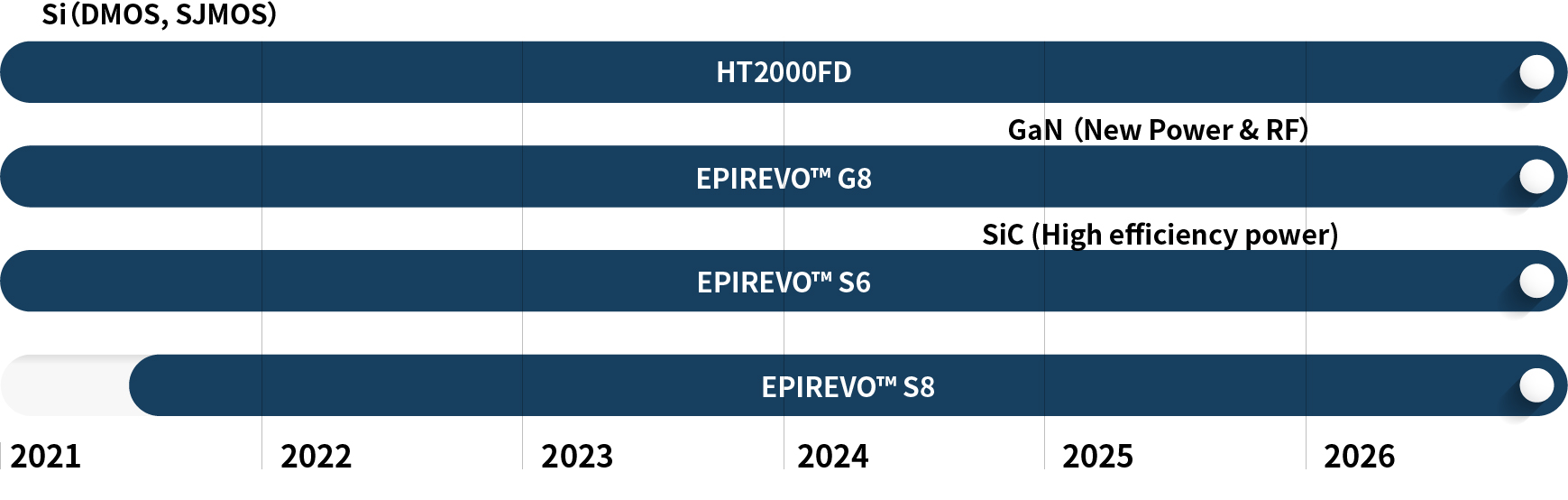

Development Roadmap

Epitaxial growth systems are process that form a layer of monocrystalline material on a silicon wafer along a uniform crystalline direction. NuFlare Technology released CVD system 「EPIREVO™ S6」 、「EPIREVO™ S8」 for silicon carbide(SiC) devices and 「EPIREVO™ G8」 for gallium-nitride-on-silicon (GaN-on-Si) devices. Those systems are developed by high-speed wafer rotation technology of Si epitaxial growth system 「HT2000FD」.※We have discontinued the production of 「HT2000FD」 (only providing maintenance services).